DiVYA

PHONE : +91-8374485831,

Mail : storagetankshy@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

Air Jet Aviation Fuel Piping System Design Services

Piping Design Consultants- Air Jet Aviation Fuel Piping | Divya Engineering

"Divya Engineering offers expert piping design consultancy services specializing in Air Jet Aviation Fuel Piping systems. We provide innovative and cost-effective solutions tailored to your project needs

Air jet aviation fuel piping refers to the specialized piping system designed to transport aviation fuel to aircraft, fuel storage tanks, and fueling stations. The system needs to meet strict standards for safety, durability, and reliability due to the critical role aviation fuel plays in the performance of an aircraft and the need to prevent any fuel contamination, leaks, or malfunctions.

Key considerations in designing and installing air jet aviation fuel piping systems:

-

Material Selection:

-

Corrosion Resistance: The piping material must be resistant to corrosion from the fuels, environmental conditions, and exposure to UV rays. Common materials used include carbon steel, stainless steel, and aluminum. Stainless steel is often preferred because it resists corrosion and is highly durable.

-

Non-Contaminating: The piping material should not react with or contaminate the fuel. In some cases, coatings or special linings are used to prevent this.

-

-

Pressure and Temperature Resistance:

-

The piping system must be capable of handling the high-pressure requirements of aviation fuel and any temperature extremes it might experience, especially during fueling and when the aircraft is in flight.

-

-

Fuel Types:

-

Different types of aviation fuels (like Jet A, Jet A-1, JP-8, etc.) may have slightly different characteristics, so the piping system needs to be suitable for the specific fuel in use. For example, Jet A and Jet A-1 are widely used for commercial aviation, while JP-8 is used in military aircraft.

-

-

Flow Rates:

-

Fuel transfer rates are critical, especially in airports with high traffic volumes. The piping system must allow for fast fueling of large aircraft without causing excessive pressure drop or fuel surges.

-

-

Fittings and Valves:

-

Special fuel-grade fittings, valves, and seals are used to ensure the system can be properly shut off, controlled, and maintained without leaks. These components must meet rigorous safety standards to ensure the integrity of the fuel system.

-

-

Safety and Environmental Concerns:

-

Leak Detection: The piping system must be equipped with leak detection technology to prevent fuel loss and mitigate the risk of spills, which can be hazardous and costly.

-

Grounding: Proper grounding of the fuel piping and fueling equipment is necessary to prevent electrostatic discharge, which could lead to sparks and ignition of fuel vapors.

-

-

Maintenance and Inspection:

-

Routine inspections are vital to ensure the integrity of the system, check for corrosion, leaks, and other potential hazards. Non-destructive testing (NDT) methods, such as ultrasonic testing or X-ray, are often used to inspect the piping without causing damage.

-

-

Compliance with Regulations:

-

Aviation fuel piping systems must adhere to strict regulations from organizations like the FAA (Federal Aviation Administration), ISO (International Organization for Standardization), and API (American Petroleum Institute). These standards cover design, material selection, installation, and maintenance.

-

-

Piping Layout:

-

Simplicity is key to minimizing the risk of blockages, leaks, and contamination. Piping layout should be planned for easy maintenance and efficient fuel flow while reducing bends or other obstructions.

-

The layout should also consider drainage to prevent fuel accumulation in low points of the system, which can cause contamination or clogging.

-

-

Fire Safety:

-

Given that aviation fuel is highly flammable, the piping system must be installed with adequate fire prevention measures. Fireproof coatings or insulation may be used, and fire-resistant materials are often selected for the components.

AIR JET AVIATION FUEL PIPING DESIGN AND DRAFTING

Air Jet Aviation Fuel Piping Design Services

Divya Engineering is a leading consultancy specializing in the design and optimization of Air Jet Aviation Fuel (AJAF) piping systems. The company’s expertise is centered around industries where the integrity of fuel transportation systems is paramount, such as aviation, oil and gas, petrochemicals, and power generation. Divya Engineering offers a full spectrum of services, from creating detailed CAD drawings and conducting pipe stress analysis to providing 3D modeling and fabrication/erection drawings. The company is committed to ensuring that each design is optimized for both performance and safety, complying with critical industry standards like ASME B31.1 and ASME B31.3. Along with their core offerings, Divya Engineering is also renowned for serving diverse industries by providing innovative solutions in piping layout optimization, stress analysis using CAESAR II, and creating Piping and Instrumentation Diagrams (P&IDs).

AIR JET AVIATION FUEL PIPING LAYOUT AND ROUTING

AJAF Piping Design and Engineering Expertise

Divya Engineering’s approach to designing Air Jet Aviation Fuel systems incorporates a wide range of specialized services, all of which are essential for creating reliable, efficient, and safe fuel transportation systems. One of the most critical phases in design is Piping Layout and Routing, which ensures that AJAF systems are engineered to meet both performance requirements and safety regulations in aviation fuel transportation.

This process is fundamental for both industrial and aviation applications, ensuring the effective transport of aviation fuel while optimizing system efficiency, space usage, and access for maintenance. To achieve the best results, Divya Engineering employs cutting-edge tools to model, visualize, and plan piping systems with precision.

Tools Used for Piping Layout and Routing:

-

AutoCAD: The industry standard for both 2D and 3D design, AutoCAD is used extensively to create detailed piping layouts and routing plans for AJAF systems, ensuring that all components are positioned accurately and according to specifications.

-

Revit: Used for Building Information Modeling (BIM), Revit helps visualize and manage complex piping systems, integrating them into broader structural and engineering designs, improving collaboration between teams.

-

Plant 3D: This advanced software is used for modeling, optimizing routing, and enhancing the design accuracy of AJAF systems, ensuring that the final layout meets operational and safety requirements.

AIR JET AVIATION FUEL PIPING SUPPORT DESIGN

A key element of Air Jet Aviation Fuel piping design is Piping Support Design, which ensures the structural integrity of systems subjected to extreme temperatures, vibrations, and potentially corrosive environments. Divya Engineering’s team specializes in designing robust supports, hangers, and brackets to secure pipes, minimizing the risk of system failure. By using advanced stress analysis tools like CAESAR II and AutoCAD Plant 3D, as well as BIM platforms like Revit, the company ensures the piping system can withstand mechanical stresses.

AIR JET AVIATION FUEL PIPING MATERIAL SELECTION

Material Selection for AJAF Systems

When designing Air Jet Aviation Fuel systems, material selection is critical to ensuring long-term performance. Divya Engineering helps clients choose materials that are durable, resistant to the unique challenges posed by aviation fuels, and suitable for extreme operating conditions. Factors like pressure tolerance, temperature resistance, and corrosion resistance are carefully considered to ensure the longevity and efficiency of the system.

AIR JET AVIATION FUEL PIPING STRESS ANALYSIS

Piping Stress Analysis and Compliance

Piping Stress Analysis is another essential service, particularly for systems designed to transport aviation fuel, which must withstand pressure surges, thermal expansion, and external loads. Divya Engineering conducts thorough analyses to ensure that AJAF systems are both durable and safe, using industry-leading software like CAESAR II to simulate and evaluate the stresses placed on piping. Compliance with industry standards is paramount, with Divya Engineering adhering to:

-

ASME B31.3: Governs the design of process piping systems, ensuring systems are robust enough to handle corrosive fluids such as aviation fuel.

ASME B31.1: Covers power piping systems, including those used in systems that transport fuels and other high-temperature, high-pressure liquids

AIR JET AVIATION FUEL PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

P&IDs and Specification Development

As part of their comprehensive services, Divya Engineering creates Piping and Instrumentation Diagrams (P&IDs) for AJAF systems. These diagrams detail the components and layout of the piping system, including valves, pumps, instrumentation, and control systems. P&IDs help simplify system troubleshooting and maintenance while ensuring safe operation. Along with P&IDs, Divya Engineering develops clear piping specifications and standards that outline the necessary parameters for the installation, operation, and maintenance of AJAF systems. These specifications guarantee that the system complies with both local and international standards, ensuring reliability and safety.

AIR JET AVIATION FUEL DEVELOPMENT OF PIPING SPECIFICATIONS AND STANDARDS

Advanced Modeling and Hydraulic Calculations

To optimize the efficiency and cost-effectiveness of the AJAF system, Divya Engineering employs hydraulic calculations and advanced pipe sizing methods. This ensures the system performs at peak efficiency while reducing operational costs.

AIR JET AVIATION FUEL PIPE SIZING AND HYDRAULIC CALCULATIONS

Advanced Modeling and Hydraulic Calculations

To optimize the efficiency and cost-effectiveness of the AJAF system, Divya Engineering employs hydraulic calculations and advanced pipe sizing methods. This ensures the system performs at peak efficiency while reducing operational costs

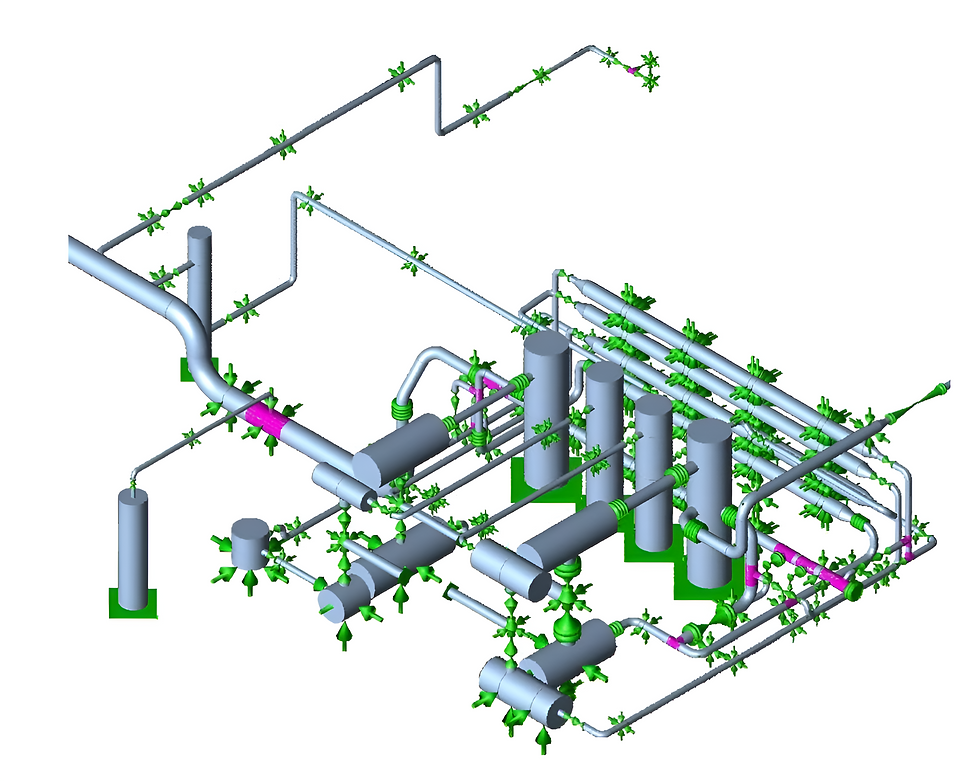

AIR JET AVIATION FUEL 3D MODELING AND DESIGN

With the use of 3D modeling technology, Divya Engineering provides highly accurate visual representations of the entire piping system, which allows for better planning, reduced errors, and more reliable construction outcomes. This 3D approach minimizes the risk of rework and ensures a smoother transition from design to construction.

AIR JET AVIATION FUEL ISOMETRIC/FABRICATION/ERECTION DRAWINGS

Isometric, Fabrication, and Erection Drawings

Once the design phase is complete, Divya Engineering produces a detailed set of Isometric Drawings, Fabrication Drawings, and Erection Drawings. These drawings are crucial for the precise construction and installation of the AJAF system, ensuring each component is correctly fabricated, assembled, and installed. Isometric drawings provide a 3D perspective of the entire system, while fabrication drawings offer detailed information on individual components and materials. Erection drawings guide the on-site assembly process, ensuring that the final installation aligns with the design specifications.

By providing these comprehensive services, Divya Engineering ensures the successful design, implementation, and operation of Air Jet Aviation Fuel piping systems that are not only safe and reliable but also efficient and durable in the demanding aviation industry. Their commitment to quality, innovation, and compliance guarantees the highest standards for aviation fuel transportation.

Air Jet Aviation Fuel Piping Design Services

Piping Design Consultants- Air Jet Aviation Fuel Piping | Divya Engineering

Piping Design and Drafting: Creating detailed CAD drawings and design calculations for Air Jet Aviation Fuel piping systems used in power plants, refineries, and other industrial facilities.

Pipe Stress Analysis: Performing static and dynamic stress analysis using software like CAESAR II to ensure the Air Jet Aviation Fuel piping system can withstand operational and environmental stresses.

3D Modeling and Design: Using software such as PDS, PDMS, or Auto Plant to create 3D models of Air Jet Aviation Fuel piping systems for better visualization and accuracy.

Isometric/Fabrication/Erection Drawings: Preparing detailed drawings for the fabrication and installation of Air Jet Aviation Fuel piping systems.

Support Detail Drawing Preparation: Designing and detailing the necessary supports for the Air Jet Aviation Fuel piping system to ensure stability and safety.

Project Management: Managing the entire Air Jet Aviation Fuel piping design project from initial conceptualization through fabrication and commissioning.

Compliance with Standards: Ensuring that the design complies with relevant standards such as ASME B31.1 for power piping and ASME B31.3 for process piping.

BILL OF MATERIAL, INSULATION & EXPANSION JOINTS

Challenges Air Jet Aviation Fuel Piping System design

Designing Air Jet Aviation Fuel Piping Systems presents several unique and complex challenges due to the specific requirements of the aviation industry and the hazardous nature of jet fuel. Below are the key challenges involved in designing these systems:

1. Safety and Risk Management:

The most significant challenge in designing aviation fuel piping systems is ensuring the highest levels of safety. Aviation fuel is highly flammable, and any leak, rupture, or system failure can have catastrophic consequences. Designers must incorporate fail-safe features such as emergency shut-off valves, fire suppression systems, pressure relief devices, and leak detection mechanisms to minimize risks to personnel, equipment, and the environment.

2. Material Selection:

Aviation fuel systems must be designed to handle the corrosive effects of jet fuel, which can degrade certain materials over time. Designers need to carefully select materials that are resistant to corrosion, erosion, and wear, including stainless steel, specialized alloys, and composite materials. The challenge lies in balancing material cost with long-term durability and performance.

3. Temperature and Pressure Variations:

Jet fuel piping systems must function efficiently across a wide range of temperatures and pressures. These systems are exposed to varying environmental conditions and must operate within a specific temperature range, which can fluctuate depending on altitude and weather. The piping design needs to accommodate the thermal expansion and contraction of materials, as well as any pressure changes, without causing stress or damage to the system.

4. Fluid Flow and Pressure Control:

Ensuring consistent fuel flow at the right pressure is crucial for proper aircraft refueling operations. Designing systems that can handle varying flow rates while maintaining optimal pressure is a challenge. The design must include appropriate pumps, valves, and pressure regulators to maintain stable conditions, prevent fuel starvation, and avoid over-pressurization, which could cause system failure.

5. Leak Prevention and Detection:

Fuel leaks in aviation fuel systems can be dangerous and costly. To mitigate the risks, the piping design must prevent leaks at every joint and connection, and ensure that any potential leaks are quickly detected. This often involves using specialized gaskets, seals, and leak detection technologies. The design must also facilitate regular inspection and maintenance to monitor the system for signs of wear or leaks.

6. Fire and Explosion Hazard Mitigation:

Because aviation fuel is highly combustible, the design must account for fire and explosion risks. This involves incorporating fire-resistant materials, proper grounding of components to prevent static discharge, and designing systems that minimize fuel spillage. Additionally, fire suppression systems must be integrated to respond effectively in the event of a fire or explosion.

7. Environmental Impact:

Fuel spills or leaks can have a severe environmental impact. In the design process, systems must be designed to minimize the risk of contamination to surrounding areas. This may involve containment systems, such as secondary containment piping, and ensuring compliance with environmental regulations regarding fuel handling and spill containment.

8. System Integration with Existing Infrastructure:

Aviation fuel systems are often integrated into existing airport infrastructure, including storage tanks, fuel pumps, and refueling stations. The design must ensure seamless integration with these systems, while also considering upgrades or modifications to meet current standards and operational needs. Proper coordination with other facility systems, such as electrical and safety monitoring systems, is essential for the smooth operation of the entire fueling process.

9. Space Constraints:

Airports and fueling stations are often busy environments with limited space for additional piping systems. Designers must optimize the use of available space, considering factors such as pipe routing, accessibility for maintenance, and avoiding interference with other systems. Compact design solutions are essential to ensure efficient installation and safe operation.

10. Regulatory Compliance:

Aviation fuel systems must comply with stringent industry regulations and standards, such as those set by the Federal Aviation Administration (FAA), National Fire Protection Association (NFPA), and American Petroleum Institute (API). Meeting these standards can be challenging due to the complexity of the regulations, and it is essential to ensure that all components, materials, and designs are fully compliant with safety and operational guidelines.

11. Maintenance and Inspection Access:

Ensuring that the piping system is accessible for routine maintenance, inspection, and repair is a significant challenge. Aviation fuel systems must be regularly checked for wear, leaks, and any signs of corrosion or damage. The design should allow for easy access to critical components without disrupting ongoing operations, especially in a busy airport environment.

12. Cost Management:

The materials, components, and technology required for designing a high-quality aviation fuel piping system can be costly. Balancing cost-efficiency with safety, durability, and compliance is a continuous challenge. Designers must consider long-term operational costs, including maintenance, while staying within budget constraints.

Overcoming these challenges requires a thorough understanding of aviation fueling systems, specialized knowledge in material science, and a strong focus on safety and regulatory compliance. The goal is to design a system that is not only effective and efficient but also secure and sustainable, ensuring smooth and safe refueling operations.

ChatGPT can make mistakes. Check important info.