DiVYA

PHONE : +91-8374485831,

Mail : storagetankshy@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

Double-walled pipe Design Services

Piping Design Consultants- Double Wall Piping | Divya Engineering

"Divya Engineering offers expert piping design consultancy services specializing in Double Wall Piping systems. We provide innovative and cost-effective solutions tailored to your project needs

Double wall piping refers to a type of pipe system designed with two concentric layers of piping, where the outer layer provides secondary containment in case of leakage or failure of the inner layer. It is commonly used in industries that handle hazardous or sensitive fluids, gases, or chemicals, ensuring safety and preventing environmental contamination.

Here’s a breakdown of double wall piping:

Key Features:

-

Primary and Secondary Layers:

-

The inner pipe (primary layer) carries the process fluid.

-

The outer pipe (secondary layer) acts as a protective barrier, capturing any potential leakage from the inner pipe before it escapes into the surrounding environment.

-

-

Leak Detection:

-

Many double wall systems include a monitoring or leak detection feature between the two walls, which can help identify potential issues like leaks early.

-

-

Enhanced Safety:

-

The design is ideal for systems where leaks could be hazardous, such as when transporting chemicals, flammable liquids, or other potentially dangerous substances.

-

-

Applications:

-

Chemical plants: To prevent the leakage of toxic or corrosive chemicals.

-

Oil and gas: For transporting fuels or other hazardous materials.

-

Waste management: For handling waste water or other waste materials where leakage could be harmful.

-

Food and pharmaceutical: When contamination must be strictly avoided.

-

Advantages:

-

Prevents Environmental Contamination: The outer pipe prevents leaks from reaching the environment, which is particularly crucial in regulated industries.

-

Reduces Downtime: Leak detection systems allow for early identification of issues, potentially reducing expensive downtime.

-

Complies with Regulations: Many industries are required to use double wall piping as part of their environmental or safety compliance standards.

Types of Double Wall Piping:

-

Metal Double Wall Piping: Typically made from materials like stainless steel or carbon steel, these are common in industrial settings.

-

Plastic Double Wall Piping: Used for non-corrosive fluids, often in chemical processing or waste handling.

Would you like more specific inf

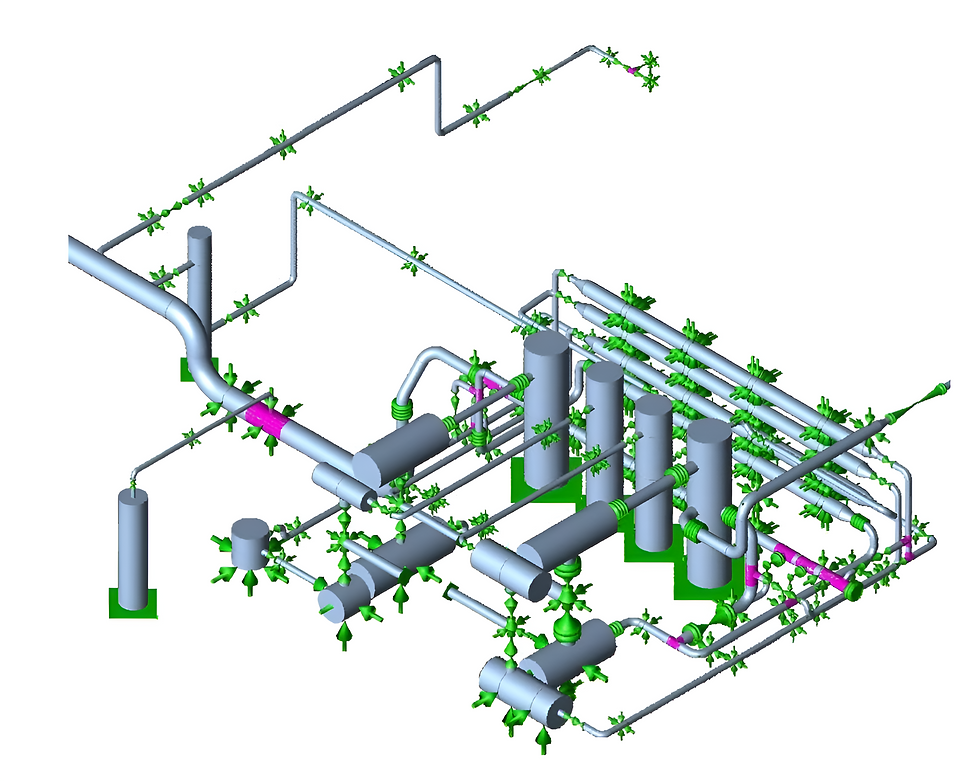

DOUBLE-WALLED PIPE DESIGN AND DRAFTING

Divya Engineering offers specialized Piping Design and Drafting services for double-walled pipe applications. They create detailed CAD drawings and perform design calculations for double-walled pipe systems used in power plants, refineries, and other industrial facilities. Divya Engineering

Key Aspects of Their double-walled pipe Design and Drafting Services:

-

Thermal Expansion Management: Designing systems to accommodate thermal expansion and contraction, preventing stress and potential damage.Divya Engineering.

-

3D Modeling: Utilizing software such as PDS, PDMS, or Auto Plant to create 3D models for enhanced visualization and accuracy in design.

-

Detailed Drawings: Preparing isometric, fabrication, and erection drawings to guide the construction and installation phases effectively.

DOUBLE-WALLED PIPE LAYOUT AND ROUTING

Divya Engineering provides specialized services in Piping Layout and Routing for double-walled pipe applications. Their expertise includes determining optimal pipe layouts to ensure efficient flow, minimize pressure drops, and prevent interference with other equipment or structures. Divya Engineering

Key Aspects of Their Piping Layout and Routing Services:

-

Efficient Flow Design: Strategically planning pipe routes to facilitate smooth fluid movement, reducing energy losses and enhancing system performance.

-

Pressure Drop Minimization: Designing layouts that minimize resistance to flow, thereby reducing pressure losses and improving overall efficiency.

-

Conflict Avoidance: Ensuring that the piping design does not clash with existing equipment, structures, or other utilities, simplifying installation and maintenance.

-

Compliance with Standards: Adhering to industry standards and regulations to ensure safety, reliability, and regulatory compliance in all design aspects.

DOUBLE-WALLED PIPE SUPPORT DESIGN

Divya Engineering provides specialized services in Piping Support Design for double-walled pipe systems. They focus on designing and specifying supports that properly secure and stabilize the piping system, preventing excessive stress and vibration.

Key Aspects of Their Piping Support Design Services:

-

Support Detail Drawing Preparation: Developing detailed drawings for supports to ensure the stability and safety of the piping system. Divya Engineering

-

Stress and Vibration Control: Designing supports that effectively manage thermal expansion, pressure-induced stresses, and vibrations, thereby maintaining the integrity of the system.

-

Compliance with Standards: Ensuring that all support designs adhere to relevant industry standards and regulations, such as ASME B31.1 and ASME B31.3, to guarantee safety and reliability.

DOUBLE-WALLED PIPE MATERIAL SELECTION

Divya Engineering offers Piping Material Selection services for double-walled pipe applications. They assist in selecting appropriate pipe materials based on factors such as the fluid being transported, operating temperature and pressure, and corrosion considerations. Divya Engineering

Key Aspects of Their Piping Material Selection Services:

-

Fluid Compatibility: Choosing materials that are compatible with the specific fluids to prevent corrosion, erosion, or chemical reactions that could compromise the system's integrity.

-

Operating Conditions: Assessing temperature and pressure conditions to select materials that can withstand the thermal and mechanical stresses encountered during operation.

-

Corrosion Resistance: Evaluating environmental factors to select materials with appropriate corrosion resistance, ensuring the longevity and reliability of the piping system.

DOUBLE-WALLED PIPE STRESS ANALYSIS

Divya Engineering provides Piping Stress Analysis services for double-walled pipe applications. They perform both static and dynamic stress analyses using specialized software like CAESAR II to ensure that piping systems can withstand operational and environmental stresses. Divya Engineering

Key Aspects of Their Piping Stress Analysis Services:

-

Thermal Expansion Management: Evaluating how temperature changes affect pipe expansion and contraction, and designing supports and restraints to accommodate these movements.

-

Creep and Fatigue Assessment: Analyzing the long-term effects of sustained high temperatures on materials to prevent deformation and failure.

-

Stress and Strain Evaluation: Identifying areas of potential overstress due to pressure, temperature, and mechanical loads to enhance system reliability.

-

Compliance with Industry Standards: Ensuring analyses meet relevant codes and standards, such as ASME B31.1 and ASME B31.3, for safety and performance.

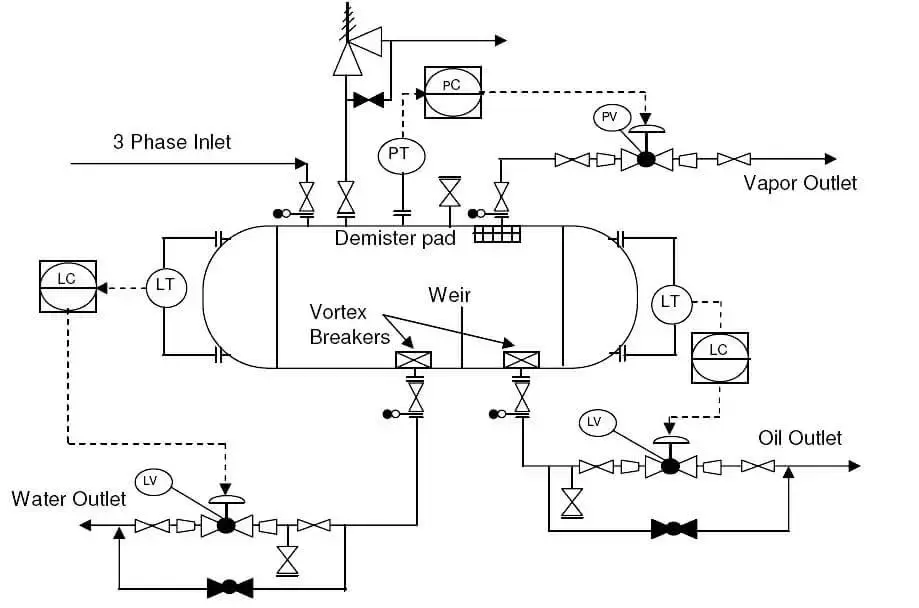

DOUBLE-WALLED PIPE AND INSTRUMENTATION DIAGRAMS (P&IDS):

Divya Engineering offers Piping and Instrumentation Diagrams (P&IDs) services for double-walled pipe applications. They develop detailed P&IDs that illustrate the piping system, including components, instrumentation, and control systems, providing a clear and comprehensive representation of the process flow and control mechanisms. Divya Engineering

Key Aspects of Their P&ID Services:

-

Detailed Representation: Creating precise diagrams that depict all piping components, instrumentation, and control systems to ensure clarity in design and operation.

-

Process Understanding: Developing P&IDs that enhance the understanding of process flows, aiding in troubleshooting, maintenance, and optimization of the system.

-

Compliance and Standards: Ensuring that all P&ID drawings adhere to relevant industry standards and regulations, facilitating smooth project approvals and operational safety.

DEVELOPMENT OF DOUBLE-WALLED PIPE SPECIFICATIONS AND STANDARDS

Divya Engineering offers services in developing Piping Specifications and Standards for double-walled pipe systems. They create detailed specifications and standards for piping materials, fabrication, and installation, ensuring consistency, quality, and compliance with industry regulations throughout the project lifecycle. Divya Engineering

Key Aspects of Their Piping Specifications and Standards Development:

-

Material Selection: Choosing appropriate materials based on factors such as fluid compatibility, operating temperature, pressure, and potential corrosion risks. Divya Engineering

-

Fabrication Guidelines: Establishing clear guidelines for the fabrication process to ensure that all components meet the required quality and performance standards.

-

Installation Procedures: Developing standardized installation procedures to maintain consistency and quality across all aspects of the piping system.

-

Compliance Assurance: Ensuring that all specifications and standards adhere to relevant industry codes and regulations, facilitating smooth project approvals and operational safety.

DOUBLE-WALLED PIPE SIZING AND HYDRAULIC CALCULATIONS

Divya Engineering offers Pipe Sizing and Hydraulic Calculations services for double-walled pipe applications. They calculate appropriate pipe sizes and perform hydraulic analyses to ensure desired flow rates and pressure drops, optimizing system efficiency and performance.

Key Aspects of Their Services:

-

Pipe Sizing: Determining optimal pipe diameters to handle specific flow rates while minimizing material costs and energy losses.

-

Hydraulic Analysis: Evaluating pressure drops and flow characteristics using established equations and software tools to design efficient piping systems.

3D MODELING AND DESIGN DOUBLE-WALLED PIPE

Divya Engineering offers 3D Modeling and Design services for double-walled pipe systems. We utilize advanced software like PDS, PDMS, and Auto Plant to create detailed 3D models, enhancing visualization and accuracy in their designs.

Benefits of Their 3D Modeling and Design Services:

-

Enhanced Visualization: 3D models provide a clear cut representation of the piping system, aiding in understanding complex designs and facilitating better decision-making.

-

Improved Accuracy: Utilizing advanced modeling software helps to detecting and resolving potential design conflicts early in the process, reducing errors during implementation.

-

Efficient Collaboration: Detailed 3D models serve as effective communication tools among project stakeholders, ensuring alignment and streamlining project workflows.

ISOMETRIC/FABRICATION/ERECTION DRAWINGS DOUBLE-WALLED PIPE

Divya Engineering offers comprehensive services in preparing Isometric, Fabrication, and Erection Drawings for double-walled pipe piping systems. These detailed drawings are essential for the accurate fabrication and installation of piping systems, ensuring that all components fit together seamlessly during construction. Divya Engineering

Key Aspects of Their Drawing Services:

-

Isometric Drawings: Providing clear representations of piping systems, highlighting dimensions and spatial relationships, which are crucial for accurate fabrication and assembly.

-

Fabrication Drawings: Delivering detailed drawings that outline the specifications and dimensions of each piping component, facilitating precise manufacturing processes.

-

Erection Drawings: Creating comprehensive plans that guide the on-site assembly of piping systems, ensuring correct placement and integration with existing structures.