DiVYA

PHONE : +91-8374485831,

Mail : storagetankshy@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

FRP Piping Design Services

Piping Design Consultancy - FRP Piping System Solutions | Divya Engineering

"Divya Engineering offers expert piping design consultancy services specializing in FRP piping systems. We provide innovative and cost-effective solutions tailored to your project needs."

FRP PIPING DESIGN AND DRAFTING

Divya Engineering is a consultancy that specializes in providing comprehensive design services for FRP piping systems. Their offerings include detailed CAD drawings, design calculations, pipe stress analysis, D modeling, and the preparation of fabrication and erection drawings. They emphasize material selection, support detail design, project management, and ensure compliance with relevant standards such ASME B31.1 and ASME B31.3 Beyond FRP piping systems, Divya Engineering also serves various sectors, including oil and gas, petrochemicals, and power plants, offering services such as piping layout and routing optimization, piping support design, stress analysis using tools CAESAR II, the development of Piping and Instrumentation Diagrams (P&IDs), and more.

FRP PIPING LAYOUT AND ROUTING

Divya Engineering's FRP Piping Design Services likely include Piping Layout and Routing, which is an essential aspect of designing FRP distribution systems for applications, such as residential, commercial, and industrial settings. This service ensures that FRP is transported efficiently and safely through the piping network, while considering space constraints, system performance, and ease of maintenance. **Software Tools Used for Piping Layout and Routing** · AutoCAD: For 2 and 3D design, AutoCAD is typically used to draft FRP piping layouts and routing plans. · Revit: Often used for Building Information Modeling (BIM), which is ideal for complex FRP piping systems within buildings. · Plant 3D: Used for industrial FRP systems, this software helps in modeling, routing, and optimizing piping systems. · CAESAR II: For stress analysis and design validation, ensuring that the system can handle operational demands.

FRP PIPING SUPPORT DESIGN

Divya Engineering's FRP Piping Design Services likely include Piping Support Design, which is an aspect of any piping system, especially in FRP distribution systems. Proper piping support ensures the system is structurally, operates efficiently, and remains safe throughout its lifespan. This service involves designing supports, hang, and brackets that hold the pipes in place and prevent damage from movement, vibration, thermal expansion, and other forces. Software and Tools Used in Piping Support Design · CAESAR II: Widely used for piping stress analysis and support design. It helps in determining the effects of thermal expansion, mechanical forces, and other loads on the system. · AutoCAD Plant 3D: Used for 3D modeling of piping systems, including supports and their integration with the piping layout. · Revit: Often used for integrated design in buildings, providing accurate 3D visualization

FRP PIPING MATERIAL SELECTION

Piping Material Selection is a critical aspect of FRP piping design, and Divya Engineering's services likely include helping clients choose the most appropriate materials for their FRP distribution systems. The right material selection ensures the system is durable,-effective, and able to handle the pressures, temperatures, other conditions it will face during its lifecycle. Here's a breakdown of what P Material Selection generally involves in the context of FRP systems. Piping Selection is a vital part of FRP piping design, and Divya Engineering would help clients choose the most appropriate materials based on factors like pressure, temperature, corrosion resistance, and cost efficiency. Whether for residential, commercial, or industrial systems, selecting the right material ensures performance and long-term sustainability. If you’re looking to discuss specific materials for your projects, feel free to out.

FRP PIPING STRESS ANALYSIS

Piping Stress Analysis is an essential part of Divya Engineering FRP piping design services. It ensures that the piping system is structurally sound and can withstand the operational stresses it will encounter over its lifetime. In FRP distribution systems, stress analysis helps identify potential issues like thermal expansion, pressure surges, vibration, and mechanical load, which could lead to failures, leaks, or system degradation. **Industry Standards and Codes for Piping Stress Analysis** Divya Engineering ensures that their piping stress analysis complies with industry standards, including: - **ASME B31.3:** The standard for process piping systems, detailing the design, materials, and safety considerations for FRP and industrial piping systems. - **ASME B31.1:** Covers power piping, including steam, FRP, and other fluid systems under pressure. Piping Stress Analysis is an essential service offered by Divya Engineering.

FRP PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

Divay Engineering FRP Piping Design Services - PIPING AND INSTRUMENTATION DIAGRAMS (P&IDs): Piping and Instrumentation Diagrams (P&IDs) are essential tools in the design, operation, and maintenance of FRP piping systems. Divya Engineering's FRP Piping Design Services would likely include the development of P&IDs ensure clarity in system design, operation, and future troubleshooting. Piping and Instrumentation Diagrams (P&IDs) in FRP Piping Design

What are P&IDs?

A Piping and Instrumentation Diagram (P&ID) is a detailed graphical representation of piping system that illustrates the relationship between pipes, equipment, valves, instruments, and control systems. It shows the flow of fluids through the piping system and includes the major components such as pumps, filters, tanks, and any related instrumentation or control devices.

FRP DEVELOPMENT OF PIPING SPECIFICATIONS AND STANDARDS

When it comes to FRP piping systems, the development of piping specifications and standards is a fundamental service offered by Divya. These specifications and standards ensure that the entire piping system is designed, installed, and maintained according to consistent, reliable, and efficient practices. They help guarantee system safety, performance, longevity and compliance with local and international standards. How Divya Engineering Develops Piping Specifications and Standards The development of piping specifications and standards by Divya Engineering typically follows a systematic and phased approach to ensure comprehensive coverage and project success: Summary The development of piping specifications and standards is a critical service provided byya Engineering for FRP piping design. These specifications ensure the proper selection of materials, the correct sizing of pipes, and compliance with local standards.

FRP PIPE SIZING AND HYDRAULIC CALCULATIONS

Divya Engineering's FRP piping design services include essential aspects such as pipe sizing and hydraulic calculations, which are critical to the efficiency, reliability, and longevity of the system. Proper pipe sizing and hydraulic analysis are key to optimizing the performance of FRP systems, whether industrial, commercial, or municipal applications. 3. How Does Divya Engineering Approach Pipe Sizing and Hydraulic Calculations? At Divya Engineering, the process of pipe sizing and hydraulic calculations involves a systematic and detailed approach, ensuring that all parameters are carefully considered for optimal system performance: Pipe sizing and hydraulic calculations are key elements of the FRP piping design process, ensuring that the system performs efficiently and safely. Through accurate calculations, Divya Engineering can optimize the flow of FRP, minimize pressure losses, and select the appropriate materials.

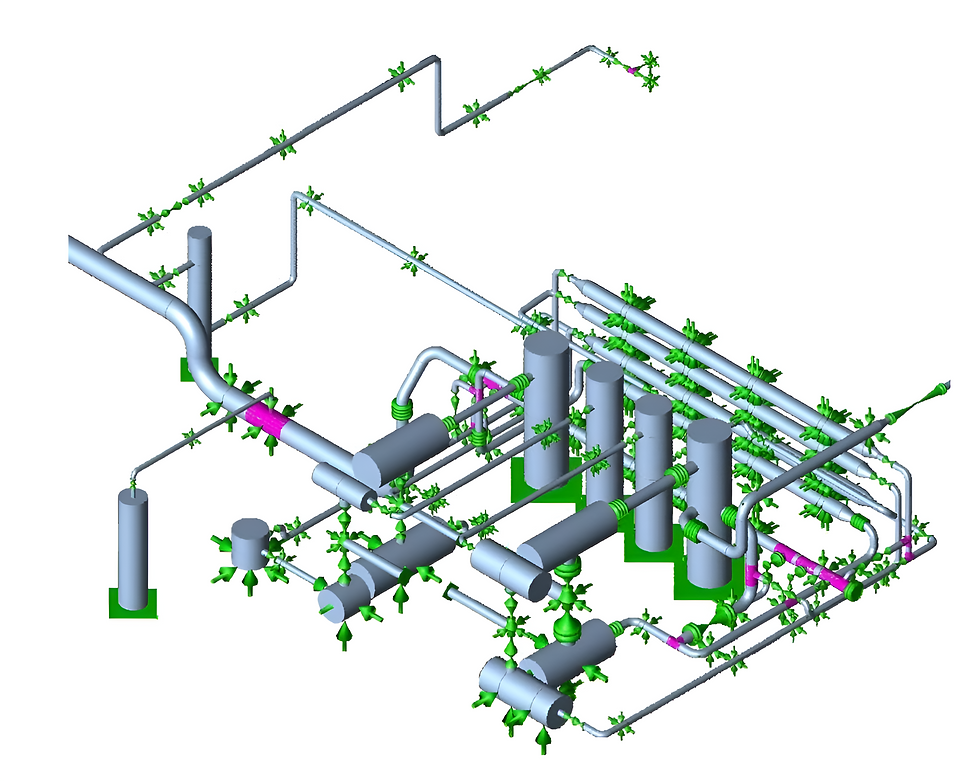

FRP 3D MODELING AND DESIGN

In the field of FRP piping design, 3D modeling and design play a crucial role in creating efficient, accurate, and visually clear representations of piping systems. Divya Engineering advanced 3D modeling and design services to ensure that FRP piping systems are precisely designed, optimized, and executed without errors or rework. Summary** 3D modeling and design are pivotal in modern FRP piping system design, and Divya Engineering leverages this technology to optimize the design process, reduce errors, and ensure that the system is efficient, cost-effective, and easy to. The ability to visualize, simulate, and analyze the entire system before construction allows for the identification of potential issues and the creation of a design that performs optimally in real-world conditions. If you're looking for a detailed and robust 3D design for your FRP piping system, Divya Engineering has the tools expertise to deliver.

FRP ISOMETRIC/FABRICATION/ERECTION DRAWINGS

At Divya Engineering, the creation of isometric, fabrication, and erection drawings is a crucial part of the FRP piping design process. drawings are essential for the successful installation and operation of the FRP system. They provide clear, accurate, and detailed instructions for the construction team, ensuring that the system is built according to the design specifications and industry standards. 1. What are Isometric, Fabrication, and Erectionings? Isometric Drawings An isometric drawing a type of 3D representation of the piping system, drawn an angle of 30 degrees to the horizontal. It is used to visually convey the layout and orientation of pipes,, valves, and other system components. Purpose: Isometric drawings are essential for conveying complex pipe layouts in a way that is easy to understand, requiring the viewer to visualize the system in three dimensions.

FRP Piping Design Services

Piping Design Consultancy - FRP Piping System Solutions | Divya Engineering

"Divya Engineering offers expert piping design consultancy services specializing in FRP piping systems. We provide innovative and cost-effective solutions tailored to your project needs."

Piping Design and Drafting:

"Divya Engineering offers expert FRP piping design and drafting services, creating detailed CAD drawings and design calculations for FRP piping systems. We specialize in serving power plants, refineries, and industrial facilities with precise, reliable solutions".

Pipe Stress Analysis:

"Divya Engineering provides comprehensive FRP pipe stress analysis using advanced software like CAESAR II. We ensure your FRP piping systems can withstand both operational and environmental stresses for optimal performance and safety."

FRP Piping and Piping Layout

"Divya Engineering specializes in FRP piping and piping layout design, offering custom solutions for efficient and reliable system configuration. Our expert team ensures optimal layout for performance, safety, and cost-effectiveness in various industrial applications."

FRP piping system Bill of Materials (BOM) and Material Take-Off (MTO)

Divya Engineering provides detailed FRP piping system Bill of Materials (BOM) and Material Take-Off (MTO) services, ensuring accurate and cost-effective procurement for your projects. Our solutions streamline the material management process for optimal project efficiency

3D Modeling and Design:

"Divya Engineering utilizes advanced software like PDS, PDMS, and AutoPlant to create precise 3D models of FRP piping systems. Our innovative approach enhances visualization, accuracy, and efficiency in design and implementation."

Isometric/Fabrication/Erection Drawings:

Preparing detailed drawings for the fabrication and installation of FRP piping systems.

Support Detail Drawing Preparation:

Designing and detailing the necessary supports for the FRP piping system to ensure stability and safety.

Project Management: Managing the entire FRP piping design project from initial conceptualization through fabrication and commissioning.

Compliance with Standards:

Ensuring that the design complies with relevant standards such as ASME B31.1 for power piping and ASME B31.3 for process piping.

BILL OF MATERIAL, INSULATION & EXPANSION JOINTS

Challenges in FRP Piping Design

While Fiber Reinforced Plastic (FRP) piping systems offer numerous advantages, such as corrosion resistance, lightweight construction, and cost-effectiveness, designing FRP piping can present a unique set of challenges. Addressing these challenges requires a deep understanding of the material properties and the specific requirements of each project. Some of the key challenges in FRP piping design include:

1. Material Selection

FRP pipes are made using various resin and reinforcement materials, each having different properties. Selecting the appropriate combination of resin, fibers, and additives is critical to ensure the pipe's performance under specific environmental conditions. Factors such as chemical resistance, temperature tolerance, pressure ratings, and durability need to be considered to select the most suitable material.

2. Design Codes and Standards

Unlike metal piping systems, FRP piping design lacks a universal set of widely recognized codes and standards. Various industry standards and guidelines may apply, such as ASTM, ASME, and ISO, but these may not be as extensive or detailed as those for traditional piping materials. Designers must have a thorough understanding of the relevant codes and adapt them as needed to ensure compliance and safety.

3. Handling Thermal Expansion

FRP pipes experience a higher rate of thermal expansion compared to metallic materials. This expansion and contraction can lead to stresses in the piping system, which must be considered in the design. Proper allowances for thermal expansion must be made, and methods like expansion loops, supports, and flexible joints may need to be incorporated into the system design.

4. Mechanical Strength and Pressure Rating

While FRP pipes are highly resistant to corrosion, they can be more susceptible to mechanical damage such as impact, compression, or buckling under pressure. Ensuring that the design accounts for the internal pressure, external loads, and other mechanical stresses is essential to avoid system failure. Pressure ratings must be carefully calculated based on the pipe's material strength and the operational conditions.

5. Joint Design and Integrity

The design and integrity of joints in FRP piping are a significant challenge. Unlike metal pipes, FRP pipes require specialized jointing methods, such as flanged connections, adhesive bonding, or mechanical coupling. Ensuring that these joints remain leak-free, especially under high pressure or corrosive conditions, requires careful material selection and design for long-term reliability.

6. Corrosion Resistance Considerations

Although FRP materials are known for their corrosion resistance, the pipes may still be vulnerable to certain chemicals or environmental conditions. Designing a piping system that maintains its integrity over time requires a thorough understanding of the chemical exposure and environmental conditions the system will face. Protective coatings or barriers may be necessary in some cases to prevent degradation.

7. Installation and Handling

FRP pipes are lightweight compared to traditional metal pipes, which makes them easier to handle and transport. However, they can be more susceptible to damage during installation due to their brittleness under certain conditions. Careful handling and proper installation procedures are necessary to avoid cracking, especially at the joints or during the bending process.

8. Long-Term Performance and Aging

Over time, the resin in FRP pipes can degrade due to factors such as UV exposure, temperature fluctuations, or chemical reactions. This can affect the pipe's performance and longevity. Ensuring that the system design accounts for these factors, including UV protection, coatings, and regular maintenance schedules, is crucial for long-term durability.

9. Cost Considerations

While FRP piping systems can be cost-effective in certain applications, the upfront costs can be higher than traditional materials like PVC or steel. Moreover, advanced design and manufacturing processes may increase costs in some projects. Balancing the long-term benefits of FRP systems with initial expenses and project budgets requires careful financial planning and analysis.

10. Quality Control and Testing

FRP piping systems must undergo rigorous quality control to ensure that the pipes and joints meet the required standards. This includes testing for pressure ratings, chemical resistance, and structural integrity. The variability in production processes and material quality can make ensuring uniformity a challenge, and manufacturers must implement stringent testing protocols to guarantee reliable performance.

In conclusion, designing FRP piping systems involves overcoming multiple technical challenges related to material properties, mechanical strength, thermal expansion, joint integrity, and long-term performance. Successful design requires expertise in material science, engineering principles, and a detailed understanding of the project requirements. By addressing these challenges, designers can create safe, durable, and efficient FRP piping systems that meet the needs of their clients while also ensuring long-term reliability and performance.