DiVYA

PHONE : +91-8374485831,

Mail : storagetankshy@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

High Corrosive Piping System Design Services

Piping Design Consultants- High Corrosive Piping | Divya Engineering

"Divya Engineering offers expert piping design consultancy services specializing in High corrosive Piping systems. We provide innovative and cost-effective solutions tailored to your project needs

When discussing high-corrosive piping, we're typically referring to pipes that are used to transport fluids or gases that are highly corrosive to materials. Corrosion in pipelines can be a significant problem in industries like oil and gas, chemical processing, and water treatment, as it leads to failure, leaks, and safety hazards. There are a few key considerations when dealing with high-corrosive piping:

1. Materials of Construction

-

Stainless Steel: A common choice, particularly grades like 316 and 304, are highly resistant to corrosion, especially in environments where chloride exposure is a concern.

-

Alloy Materials: Nickel-based alloys, such as Hastelloy or Inconel, provide excellent resistance to extreme corrosive environments.

-

Plastic Pipes: In some cases, materials like PVC, CPVC, or polyethylene are used because they are resistant to many types of corrosive chemicals. CPVC, for instance, can handle high-temperature corrosive fluids like hot acids.

-

Fiberglass Reinforced Plastic (FRP): This is a composite material that combines the strength of fiberglass with the corrosion resistance of resin. It's often used in industrial settings where chemical exposure is high.

-

Titanium: Titanium is another high-performance material that is extremely resistant to corrosion, especially in highly reactive environments like seawater and concentrated acids.

2. Corrosion Protection Methods

-

Coatings and Linings: Even if the pipes themselves are made from a highly resistant material, applying protective coatings or internal linings (epoxy, for instance) can enhance their resistance to corrosion.

-

Cathodic Protection: This technique uses a sacrificial anode to prevent corrosion by making the pipe the cathode of an electrochemical cell. This is widely used in underground and underwater pipelines.

-

Corrosion Inhibitors: Chemical inhibitors can be added to the fluids being transported to reduce the rate of corrosion, although this can add complexity to the system.

3. Piping Applications

-

Chemical Processing: For transporting strong acids, bases, or solvents like hydrochloric acid (HCl) or sulfuric acid (H₂SO₄), special corrosion-resistant alloys or plastics are typically required.

-

Seawater Systems: Pipes that handle seawater are exposed to high levels of salinity and can quickly corrode, requiring materials like titanium, stainless steel, or FRP.

-

Oil & Gas: The transportation of natural gas and oil can involve harsh chemicals, sand, and moisture that contribute to corrosion, making corrosion-resistant materials essential in these systems.

4. Factors Influencing Corrosion

-

Chemical Composition: The specific chemicals being transported, as well as their concentration, will influence the type of corrosion and the required material.

-

Temperature: Higher temperatures can accelerate the rate of corrosion, making it important to choose materials that can withstand thermal stress.

-

Flow Velocity: High-velocity flows can increase erosion and abrasion, compounding the problem of corrosion.

HIGH CORROSIVE PIPING DESIGN AND DRAFTING

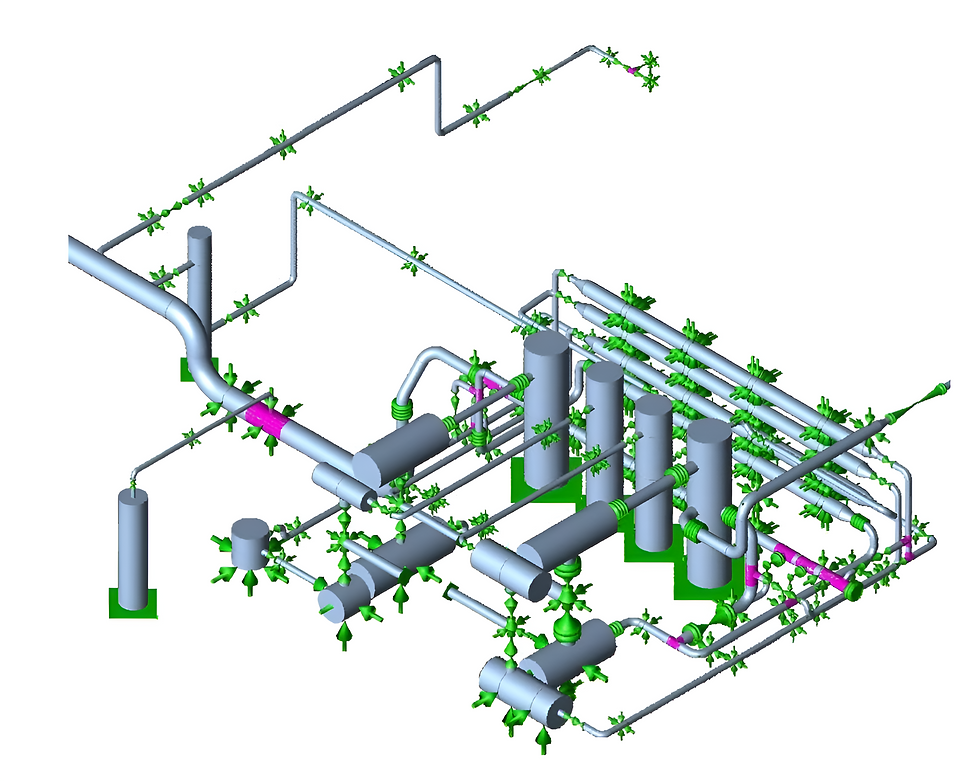

Divya Engineering is a specialized consultancy offering expert design services for high-corrosive piping systems, primarily focusing on industries where the challenge of corrosive environments is critical, such as oil and gas, petrochemicals, and power generation. Their extensive range of services includes the development of detailed CAD drawings, conducting design calculations, performing pipe stress analysis, creating 3D models, and providing fabrication and erection drawings. The team places a strong emphasis on critical design considerations like material selection, support detail design, and efficient project management while ensuring compliance with important industry standards like ASME B31.1 and ASME B31.3. In addition to high-corrosive systems, Divya Engineering also serves diverse industries, providing a broad spectrum of services including piping layout optimization, stress analysis with CAESAR II, and the creation of Piping and Instrumentation Diagrams (P&IDs).

HIGH CORROSIVE PIPING LAYOUT AND ROUTING

High-Corrosive Piping Design Services

Divya Engineering’s high-corrosive piping design services cover a wide array of essential areas, starting with Piping Layout and Routing. This process is central to designing piping systems in environments where materials must withstand aggressive, corrosive substances. It ensures safe and effective fluid transportation across diverse sectors, including residential, commercial, and industrial applications. The design process also optimizes system performance, minimizes space constraints, and enhances maintenance access.

Tools Used for Piping Layout and Routing:

-

AutoCAD: This industry-standard software is used for both 2D and 3D design, facilitating the creation of piping layouts and routing plans in high-corrosive systems.

-

Revit: Ideal for Building Information Modeling (BIM), Revit is effective for visualizing and managing high-corrosive piping systems in structural designs.

Plant 3D: Designed for industrial applications, Plant 3D helps model piping configurations, optimize routing, and enhance design accuracy for corrosive systems

HIGH CORROSIVE PIPING SUPPORT DESIGN

A key aspect of high-corrosive piping design is Piping Support Design. This service is essential for ensuring the structural integrity of piping systems subjected to corrosion, thermal expansion, vibration, and other environmental challenges. Divya Engineering designs robust supports, hangers, and brackets that secure pipes and prevent potential damage. Advanced tools like CAESAR II for stress analysis, AutoCAD Plant 3D for 3D modeling, and Revit for visual integration play a pivotal role in achieving these goals

HIGH CORROSIVE PIPING MATERIAL SELECTION

Another integral part of high-corrosive piping design is Material Selection. Divya Engineering supports clients in choosing materials that will best resist corrosion, withstand extreme operating conditions, and provide long-term system durability. Factors such as temperature resistance, pressure tolerance, and cost-effectiveness are considered to ensure the material’s ability to optimize system performance and extend its lifecy

HIGH CORROSIVE PIPING STRESS ANALYSIS

Piping Stress Analysis is a crucial service in high-corrosive piping design. This analysis ensures that the piping system can withstand the mechanical stresses encountered during operation, including those caused by thermal expansion, pressure surges, and external loads. It is vital in preventing failures, leaks, and system degradation. Divya Engineering adheres to stringent industry standards such as:

-

ASME B31.1: Covers power piping, addressing steam and fluid systems that are prone to corrosive conditions.

-

ASME B31.3: Governs process piping systems, including requirements for corrosive systems.

HIGH CORROSIVE PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

P&IDs and Specification Development

Divya Engineering also excels in creating Piping and Instrumentation Diagrams (P&IDs). These diagrams are comprehensive visual tools that detail the system’s components, including pipes, valves, instrumentation, and control systems. P&IDs are crucial for understanding fluid flow in high-corrosive piping systems and ensuring safe operation. They play a critical role in simplifying troubleshooting and ensuring consistent maintenance practices.

In addition to P&IDs, Divya Engineering develops comprehensive Piping Specifications and Standards. These specifications are essential for designing, installing, and maintaining piping systems, particularly in corrosive environments where reliability and safety are paramount. Their structured, phased methodology ensures compliance with both local and international standards and guarantees the correct selection of materials, accurate pipe sizing, and long-term system performance.

HIGH CORROSIVE DEVELOPMENT OF PIPING SPECIFICATIONS AND STANDARDS

In addition to P&IDs, Divya Engineering develops comprehensive Piping Specifications and Standards. These specifications are essential for designing, installing, and maintaining piping systems, particularly in corrosive environments where reliability and safety are paramount. Their structured, phased methodology ensures compliance with both local and international standards and guarantees the correct selection of materials, accurate pipe sizing, and long-term system performance.

HIGH CORROSIVE PIPE SIZING AND HYDRAULIC CALCULATIONS

Advanced Modeling and Hydraulic Calculations

The design process includes Pipe Sizing and Hydraulic Calculations, which are crucial for ensuring optimal system efficiency and reducing operational costs in high-corrosive environments. Divya Engineering uses a comprehensive approach to sizing and hydraulic analysis, ensuring the system is both efficient and reliable, while also contributing to cost savings and operational longevity.

HIGH CORROSIVE 3D MODELING AND DESIGN

In modern high-corrosive piping design, 3D Modeling plays a critical role. Divya Engineering employs cutting-edge 3D modeling technology to create accurate representations of piping systems, allowing for better visualization and analysis before construction. This process reduces errors and rework, ensuring a more efficient and reliable construction phase.

HIGH CORROSIVE ISOMETRIC/FABRICATION/ERECTION DRAWINGS

Finally, the development of Isometric, Fabrication, and Erection Drawings is key to translating the design into reality. These detailed drawings provide clear guidance for construction, ensuring accurate pipe assembly and installation. Isometric Drawings provide a 3D perspective of the system, while Fabrication Drawings detail individual components and materials, and Erection Drawings guide on-site assembly.

Through these extensive services, Divya Engineering ensures the design, implementation, and operation of high-corrosive piping systems that are not only efficient and reliable but also resilient against the most challenging operating conditions.

High Corrosive Piping Design Services

Piping Design Consultants- High Corrosive Piping | Divya Engineering

Piping Design and Drafting: Creating detailed CAD drawings and design calculations for High Corrosive piping systems used in power plants, refineries, and other industrial facilities.

Pipe Stress Analysis: Performing static and dynamic stress analysis using software like CAESAR II to ensure the High Corrosive piping system can withstand operational and environmental stresses.

3D Modeling and Design: Using software such as PDS, PDMS, or Auto Plant to create 3D models of High Corrosive piping systems for better visualization and accuracy.

Isometric/Fabrication/Erection Drawings: Preparing detailed drawings for the fabrication and installation of High Corrosive piping systems.

Support Detail Drawing Preparation: Designing and detailing the necessary supports for the High Corrosive piping system to ensure stability and safety.

Project Management: Managing the entire High Corrosive piping design project from initial conceptualization through fabrication and commissioning.

Compliance with Standards: Ensuring that the design complies with relevant standards such as ASME B31.1 for power piping and ASME B31.3 for process piping.

BILL OF MATERIAL, INSULATION & EXPANSION JOINTS

Challenges High corrosive Piping System design

Designing high-corrosive piping systems presents several unique challenges due to the harsh environmental conditions these systems must withstand. The design process requires careful consideration of material selection, system longevity, and safety. Below are the key challenges associated with designing high-corrosive piping systems:

1. Material Selection:

One of the most significant challenges in designing high-corrosive piping systems is selecting the right materials that can withstand aggressive chemicals, gases, or fluids. Common materials, like carbon steel, are often not suitable for highly corrosive environments. Therefore, designers must choose corrosion-resistant alloys such as stainless steel, titanium, or special coatings. However, these materials can be expensive, and selecting the most cost-effective yet durable material requires careful analysis.

2. Corrosion Resistance:

Even with corrosion-resistant materials, the system must be designed to prevent localized corrosion, such as pitting, crevice corrosion, and galvanic corrosion. These forms of corrosion can occur in areas with poor flow, poor coating coverage, or metal-to-metal contact. Engineers must design the system with features like smooth surfaces, proper coatings, and sufficient drainage to reduce these risks.

3. Chemical Compatibility:

Piping systems designed for corrosive environments must be compatible with the specific chemicals or substances they will transport. Different chemicals react differently with materials, and selecting a material that provides long-term stability and safety in a particular chemical environment is crucial. Failure to account for chemical compatibility could result in premature material degradation or failure.

4. Pressure and Temperature Extremes:

High-corrosive systems often operate under extreme pressures and temperatures. These conditions can accelerate corrosion rates and lead to material fatigue or failure. The design must accommodate these factors, ensuring that the materials used retain their integrity and function under such demanding conditions.

5. Erosion-Corrosion:

High-velocity fluids and gases can lead to both erosion and corrosion, commonly referred to as erosion-corrosion. This phenomenon occurs when the corrosive fluid flows rapidly through the piping system, causing wear and tear on the piping material. Engineers need to account for both erosion and corrosion in the design, often by choosing wear-resistant materials or adding protective linings to vulnerable areas.

6. Internal and External Corrosion Protection:

Designing for both internal and external corrosion protection is essential. Internally, the piping system may require special coatings or linings to prevent corrosion from the fluids flowing through it. Externally, environmental factors like humidity, temperature fluctuations, and exposure to chemicals can cause corrosion on the surface. Protective coatings, wraps, and sacrificial anodes are commonly used to safeguard against external corrosion.

7. Maintenance and Inspection Access:

Corrosive piping systems require frequent inspection and maintenance to ensure they are functioning properly. Designing systems that allow easy access to these pipes for regular inspections, cleaning, and maintenance without causing disruptions is a challenge. The layout must also ensure that these maintenance tasks can be done safely in hazardous environments.

8. Leak Prevention and Safety:

High-corrosive environments pose significant safety risks, including the potential for leaks and spills that could harm workers, the public, or the environment. The design must incorporate fail-safes such as pressure relief valves, monitoring systems, and high-quality seals and joints to prevent leaks. Ensuring the piping system is designed with emergency shutoff mechanisms and quick-response capabilities is critical for safety.

9. System Integration:

Corrosive piping systems often operate within larger industrial systems, and proper integration is key to ensuring the overall system's safety and functionality. Coordinating the design of the piping system with other systems, such as heat exchangers, pumps, and filtration systems, can be difficult, especially when considering material compatibility and space constraints.

10. Environmental Impact:

As corrosive fluids and gases can be harmful to the environment, the design must minimize the risk of leaks or contamination. Engineers need to consider environmental regulations and adopt environmentally friendly materials and designs that help reduce the carbon footprint and mitigate the impact on surrounding ecosystems.

11. Cost Considerations:

High-corrosive systems typically require premium materials, protective coatings, and advanced design techniques, which can significantly increase the cost of the project. Balancing durability, performance, and cost-effectiveness while adhering to client budgets is a constant challenge. Additionally, the long-term cost savings of investing in high-quality materials and proper design should be considered to reduce future maintenance and replacement costs.

12. Thermal Expansion and Contraction:

Extreme temperatures in high-corrosive environments can lead to the expansion and contraction of pipes. These movements must be accommodated in the design to prevent stress, cracking, or misalignment of the piping system. Engineers must include flexible joints, expansion loops, and proper supports to allow for thermal movement while maintaining structural integrity.

Designing high-corrosive piping systems requires a combination of specialized knowledge, innovative material selection, and rigorous engineering to overcome these challenges. The goal is to create a piping system that provides long-lasting performance, ensures safety, and minimizes maintenance requirements despite the difficult operating conditions.