DiVYA

PHONE : +91-8374485831,

Mail : storagetankshy@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

Instrument Air Piping Design Services

Piping Design consultants- Instrument Air Piping Design |Divya Engineering

(Utility piping design , water, Instrument Air, steam )

INSTRUMENT AIR PIPING DESIGN AND DRAFTING

Divya Engineering provides comprehensive Piping Design and Drafting services, specializing in creating detailed CAD drawings and design calculations for various piping systems, including those used in oil and gas, petrochemicals, power plants, and water storage tanks

"Divya Engineering offers expert piping design consultancy services specializing in Instrument Air Piping systems. We provide innovative and cost-effective solutions tailored to your project needs

Instrument air piping refers to the system of pipes, valves, and components used to transport compressed air to instruments in industrial settings. This air is often used to operate a variety of devices such as control valves, actuators, pneumatic transmitters, and other equipment that requires a steady air supply for operation.

Here’s an overview of the key aspects of instrument air piping:

1. Purpose

-

Instrument air is used for control, automation, and safety functions in plants, especially in industries such as oil & gas, chemical, pharmaceutical, and power plants.

-

It provides a clean, dry, and pressurized air supply to instruments that rely on pneumatic controls and instrumentation.

2. Key Components

-

Compressor: Provides the compressed air.

-

Air Dryer: Removes moisture to ensure the air is dry and prevents corrosion or blockages in instruments.

-

Filters: Removes impurities like dust or oil from the air.

-

Pressure Regulators: Maintain the required pressure levels for specific instruments.

-

Piping and Valves: Distribute the air supply to various parts of the plant or facility.

-

Flow Meters: Measure the flow of compressed air in the system.

3. Piping Design Considerations

-

Material Selection: Piping materials are often stainless steel, carbon steel, or other corrosion-resistant alloys, depending on the environment.

-

Pipe Sizing: It is important to size pipes correctly to maintain the required pressure and flow to the instruments. Under-sized pipes can lead to pressure drops, reducing efficiency or reliability of the system.

-

Pressure Drop: Piping design should minimize pressure drop, which can affect instrument performance. This can be achieved by using the correct pipe sizes, minimizing the number of bends, and avoiding excessive length.

-

Separation of Instrument Air from Other Systems: Instrument air should be kept isolated from other types of compressed air (such as plant air) to avoid contamination.

4. Maintenance

-

Regular inspection and maintenance of compressors, dryers, and filters are essential to ensure the air quality remains within specification.

-

Piping should be checked for leaks, wear, and blockages.

5. Air Quality

-

Dryness: The air should be free of moisture to avoid freezing in winter or causing damage to sensitive instrumentation.

-

Cleanliness: Air must be free from oil and particulates to prevent contamination or damage to instruments.

6. Control and Monitoring

-

Instrument air systems often include monitoring devices for pressure, temperature, and flow. These sensors help operators ensure the system is working correctly and maintain the air quality as per specifications.

INSTRUMENT AIR PIPING LAYOUT AND ROUTING

Divya Engineering offers Instrument Piping Design services, with a focus on Piping Layout and Routing. This service is crucial for designing the piping systems that handle fluid or gas in various industrial applications, ensuring efficiency, safety, and compliance with relevant standards. Here's a detailed overview of the Piping Layout and Routing process:

INSTRUMENT AIR PIPING SUPPORT DESIGN

Divya Engineering offers Instrument Air Piping Design Services with a special focus on Supports Design. The design and installation of appropriate supports for the instrument air piping system is a critical aspect of ensuring the safety, stability, and long-term functionality of the system. Below is a detailed explanation of what Supports Design involves in the context of Instrument Air Piping Design

Divya Engineering’s Instrument Air Piping Support Design services provide clients with a thorough, reliable, and efficient solution for maintaining the integrity of their air systems. Whether you're setting up a new installation or optimizing an existing one, their expertise ensures that all elements of your system, from piping to supports, work together in harmony to deliver optimal performance.

Benefits of Instrument Air Piping Support Design by Divya Engineering:

-

Enhanced System Stability: Properly designed supports help maintain alignment and prevent damage or excessive movement in the piping system.

-

Extended Lifespan: Supports reduce wear and tear on pipes, ensuring the system operates smoothly for longer, reducing maintenance and repair costs.

-

Improved Safety: Well-supported piping systems minimize the risk of leaks, pipe rupture, or other hazardous incidents caused by insufficient support.

-

Optimized Performance: With effective support design, the instrument air system can perform more efficiently, with minimal disruptions due to vibration or misalignment.

INSTRUMENT AIR PIPING MATERIAL SELECTION

Divya Engineering provides Instrument Air Piping Design Services, and one of the key aspects of this service is Material Selection. The material chosen for the instrument air piping system plays a crucial role in the overall performance, longevity, and safety of the system. The right material ensures that the system is resistant to corrosion, able to withstand pressure and temperature variations, and cost-effective. Below is an overview of the Material Selection process for Instrument Air Piping Design.

Divya Engineering’s Material Selection Process:

Divya Engineering follows a systematic approach to material selection for instrument air piping:

Assessment of Project Requirements: Thorough evaluation of project specifications, operational conditions, and environmental factors.

Material Recommendations: Based on the assessment, Divya Engineering recommends the most appropriate material(s) for the piping system, considering both performance and budget.

Divya Engineering’s Instrument Air Piping Design Services ensure that material selection is based on the specific needs of each project, with attention to operational requirements, safety, and budget. The right material choice is crucial to the reliability, efficiency, and cost-effectiveness of the instrument air piping system, and Divya Engineering’s expertise ensures the best solution for each unique application.

INSTRUMENT AIR PIPING STRESS ANALYSIS

Divya Engineering offers Instrument Air Piping Design Services, with a strong emphasis on Piping Stress Analysis. Piping stress analysis is a crucial step in the design of instrument air systems, ensuring that the piping remains safe, reliable, and efficient under various operational conditions. This analysis helps identify potential issues related to thermal expansion, pressure variations, mechanical forces, and vibrations that could affect the system’s integrity. Here's an overview of Piping Stress Analysis and its role in Divya Engineering’s Instrument Air Piping Design services:

Software for Piping Stress Analysis:

Divya Engineering uses industry-standard software tools to perform piping stress analysis, including:

CAESAR II: Widely used for calculating the stress, displacement, and flexibility of piping systems.

Divya Engineering’s Expertise in Piping Stress Analysis:

Divya Engineering’s team of experienced engineers is proficient in performing comprehensive piping stress analysis for instrument air systems. Their expertise ensures that:

All components of the piping system are optimally designed to handle the expected stresses.

The system will perform safely and reliably over its expected lifespan.

The project will comply with relevant engineering codes and safety standards.

Maintenance needs and potential issues are anticipated in advance, ensuring smooth operation and cost-effective management.

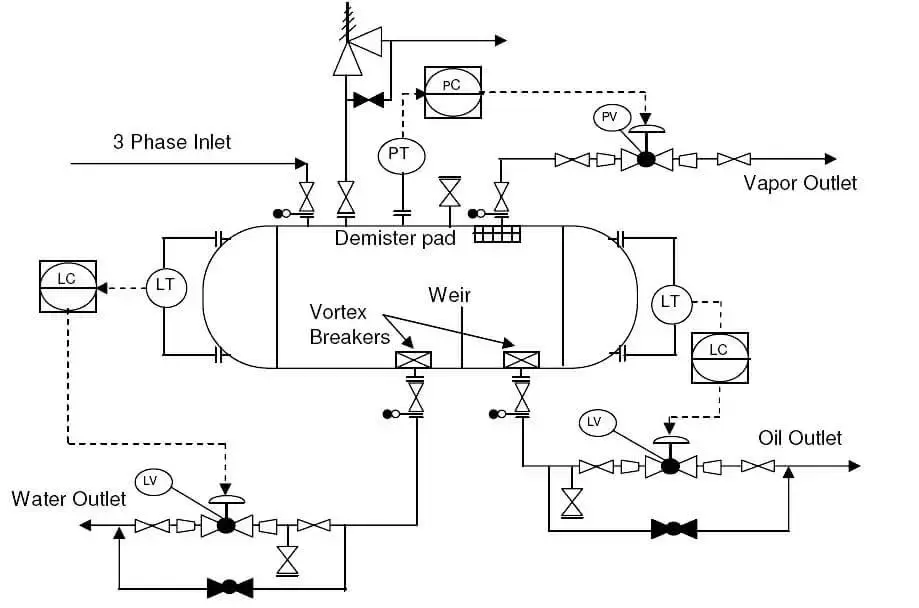

INSTRUMENT AIR PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

Divya Engineering offers Piping and Instrumentation Diagrams (P&IDs) services for utility piping applications. They develop detailed P&IDs that illustrate the piping system, including components, instrumentation, and control systems, providing a clear and comprehensive representation of the process flow and control mechanisms. Divya Engineering

Key Aspects of Their P&ID Services:

-

Detailed Representation: Creating precise diagrams that depict all piping components, instrumentation, and control systems to ensure clarity in design and operation.

-

Process Understanding: Developing P&IDs that enhance the understanding of process flows, aiding in troubleshooting, maintenance, and optimization of the system.

-

Compliance and Standards: Ensuring that all P&ID drawings adhere to relevant industry standards and regulations, facilitating smooth project approvals and operational safety.

INSTRUMENT AIR DEVELOPMENT OF PIPING SPECIFICATIONS AND STANDARDS

Divya Engineering offers services in developing Piping Specifications and Standards for utility piping systems. They create detailed specifications and standards for piping materials, fabrication, and installation, ensuring consistency, quality, and compliance with industry regulations throughout the project lifecycle. Divya Engineering

Key Aspects of Their Piping Specifications and Standards Development:

-

Material Selection: Choosing appropriate materials based on factors such as fluid compatibility, operating temperature, pressure, and potential corrosion risks. Divya Engineering

-

Fabrication Guidelines: Establishing clear guidelines for the fabrication process to ensure that all components meet the required quality and performance standards.

-

Installation Procedures: Developing standardized installation procedures to maintain consistency and quality across all aspects of the piping system.

-

Compliance Assurance: Ensuring that all specifications and standards adhere to relevant industry codes and regulations, facilitating smooth project approvals and operational safety.

INSTRUMENT AIR PIPE SIZING AND HYDRAULIC CALCULATIONS

Divya Engineering offers Pipe Sizing and Hydraulic Calculations services for high-temperature applications. They calculate appropriate pipe sizes and perform hydraulic analyses to ensure desired flow rates and pressure drops, optimizing system efficiency and performance.

Key Aspects of Their Services:

-

Pipe Sizing: Determining optimal pipe diameters to handle specific flow rates while minimizing material costs and energy losses.

-

Hydraulic Analysis: Evaluating pressure drops and flow characteristics using established equations and software tools to design efficient piping systems.

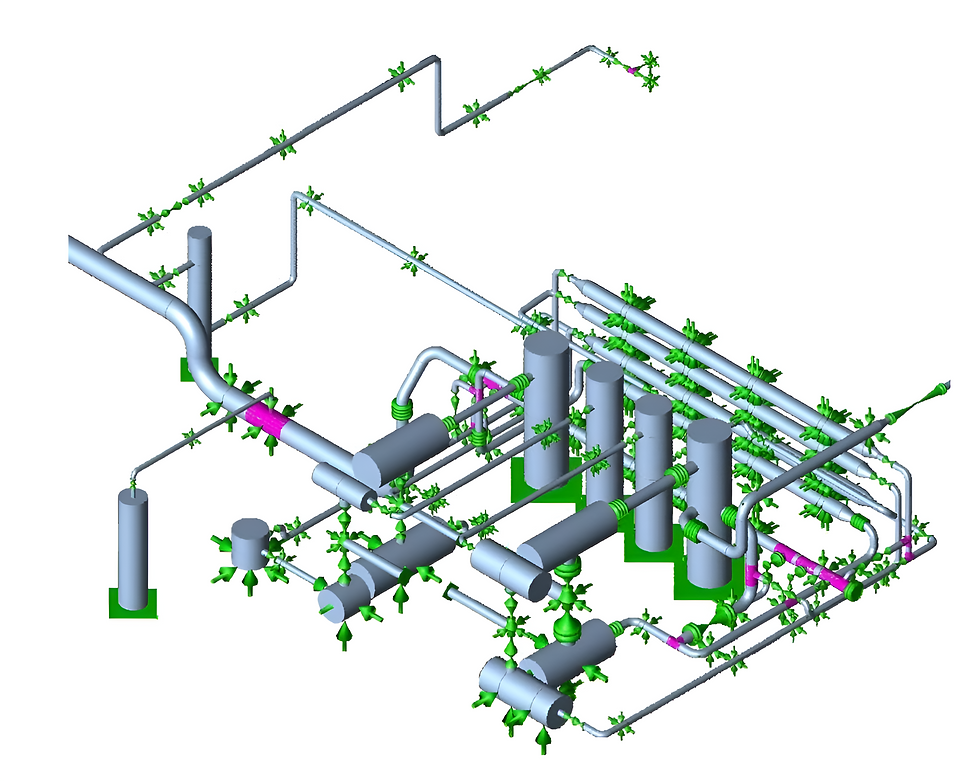

INSTRUMENT AIR 3D MODELING AND DESIGN

Divya Engineering offers 3D Modeling and Design services for high-temprature piping systems. We utilize advanced software like PDS, PDMS, and Auto Plant to create detailed 3D models, enhancing visualization and accuracy in their designs.

Benefits of Their 3D Modeling and Design Services:

-

Enhanced Visualization: 3D models provide a clear cut representation of the piping system, aiding in understanding complex designs and facilitating better decision-making.

-

Improved Accuracy: Utilizing advanced modeling software helps to detecting and resolving potential design conflicts early in the process, reducing errors during implementation.

-

Efficient Collaboration: Detailed 3D models serve as effective communication tools among project stakeholders, ensuring alignment and streamlining project workflows.

INSTRUMENT AIR ISOMETRIC/FABRICATION/ERECTION DRAWINGS

Divya Engineering offers comprehensive services in preparing Isometric, Fabrication, and Erection Drawings for high-temperature piping systems. These detailed drawings are essential for the accurate fabrication and installation of piping systems, ensuring that all components fit together seamlessly during construction. Divya Engineering

Key Aspects of Their Drawing Services:

-

Isometric Drawings: Providing clear representations of piping systems, highlighting dimensions and spatial relationships, which are crucial for accurate fabrication and assembly.

-

Fabrication Drawings: Delivering detailed drawings that outline the specifications and dimensions of each piping component, facilitating precise manufacturing processes.

-

Erection Drawings: Creating comprehensive plans that guide the on-site assembly of piping systems, ensuring correct placement and integration with existing structures.

Instrument Air Piping Design Services

Piping Design consultants- Instrument Piping piping |Divya Engineering

Piping Design and Drafting: Creating detailed CAD drawings and design calculations for Instrument Air piping systems used in power plants, refineries, and other industrial facilities.

Pipe Stress Analysis: Performing static and dynamic stress analysis using software like CAESAR II to ensure the Instrument Air piping system can withstand operational and environmental stresses.

3D Modeling and Design: Using software such as PDS, PDMS, or Auto Plant to create 3D models ofInstrument Air piping systems for better visualization and accuracy.

Isometric/Fabrication/Erection Drawings: Preparing detailed drawings for the fabrication and installation of Instrument Air piping systems.

Support Detail Drawing Preparation: Designing and detailing the necessary supports for the Instrument Air piping system to ensure stability and safety.

Project Management: Managing the entire Instrument Air piping design project from initial conceptualization through fabrication and commissioning.

Compliance with Standards: Ensuring that the design complies with relevant standards such as ASME B31.1 for power piping and ASME B31.3 for process piping.

BILL OF MATERIAL, INSULATION & EXPANSION JOINTS

Challenges in Instrument Air Piping Design

Designing Instrument Air piping systems is a critical task for ensuring the proper functioning of pneumatic equipment, instruments, and control systems in various industrial sectors such as oil and gas, power generation, and chemical processing. While these systems are essential for operational efficiency and safety, there are several challenges associated with their design and implementation. Below are some of the key challenges in Instrument Air piping design:

1. Air Quality and Filtration

Instrument air must be clean, dry, and free from contaminants such as moisture, oil, and particulate matter. Ensuring that the air quality meets the stringent requirements of the system can be challenging. The design must include adequate filtration and drying systems, such as air dryers and filters, to prevent contamination that could damage instruments and control systems. Ensuring continuous, reliable air quality over the system’s lifecycle requires careful planning and monitoring.

2. System Sizing and Pressure Requirements

Properly sizing the piping system to handle the required air flow and pressure is a critical aspect of the design. Instrument air systems must provide consistent and reliable air supply to instruments and control devices, which can be sensitive to pressure fluctuations. Calculating the correct pipe diameters, choosing the right materials, and determining the appropriate number and size of compressors and receivers is essential to maintain the desired pressure throughout the system and avoid over or under-sizing issues. Incorrect sizing can result in inefficiencies, excessive energy consumption, or inadequate pressure supply.

3. Air Compressors and Storage

Instrument air systems require reliable, high-performance air compressors to generate the required air pressure. The design challenge is selecting the appropriate type of compressor, whether it's rotary screw, reciprocating, or centrifugal, and ensuring that it can meet the demands of the system efficiently. Additionally, storage tanks (receivers) are necessary to maintain a stable pressure in the system. Proper integration of the compressors, storage tanks, and piping is required to ensure that air is supplied at a consistent pressure, and the compressors are not overloaded.

4. Temperature and Moisture Control

Compressed air, when generated, often has a higher temperature and contains moisture. If the air is not properly cooled or dried before being delivered to the instruments, the moisture can condense inside the pipes, leading to blockages, corrosion, or damage to sensitive equipment. Designing the system with appropriate cooling and moisture separation mechanisms, such as aftercoolers and separators, can be challenging. Additionally, ensuring that these systems are regularly maintained to prevent moisture buildup and maintain air quality requires careful planning.

5. Piping Material Selection

Instrument air piping must be constructed from materials that are resistant to corrosion, wear, and leakage, especially in harsh environments. Materials such as carbon steel, stainless steel, or plastic may be used, depending on the operational conditions. The challenge lies in selecting materials that are compatible with the specific air quality requirements, pressure ratings, and temperature conditions while also being cost-effective. Additionally, the material must be resistant to the buildup of contaminants like scale or rust, which could degrade the quality of the air and affect system performance.

6. Leakage and Maintenance

Leaks in instrument air systems can lead to significant operational issues, including pressure drops, energy waste, and equipment malfunction. Designing for leak prevention is crucial, and it requires selecting the right fittings, joints, and seals, and ensuring proper installation techniques. In addition, regular inspection and maintenance schedules must be factored into the design to ensure the longevity and reliability of the system. Ensuring easy access to the piping for inspection and maintenance without disrupting operations is also a key challenge.

7. Pressure Relief and Safety Considerations

Instrument air systems must be equipped with appropriate safety measures, including pressure relief valves and safety valves, to prevent over-pressurization. Over-pressurization can lead to catastrophic failure of the system or damage to sensitive equipment. Designing the system to handle pressure fluctuations and ensuring that all components are designed to withstand maximum pressure loads without failure is a critical aspect of the design.

8. Energy Efficiency

Energy consumption is a major consideration when designing instrument air systems. Compressed air systems are often energy-intensive, and ensuring that the system is as energy-efficient as possible is essential to reduce operational costs. This can involve selecting energy-efficient compressors, minimizing pressure drops, and optimizing pipe sizes to reduce friction losses. Additionally, using energy recovery systems or pressure reduction techniques can help improve overall efficiency.

9. System Integration with Other Equipment

Instrument air systems are typically integrated with a range of other industrial systems, including control valves, actuators, and other pneumatic instruments. Ensuring proper integration and coordination between the instrument air piping and other components of the plant or facility is a significant challenge. This includes maintaining consistent air pressure and quality, ensuring compatibility with other control systems, and preventing cross-contamination between different systems.

10. Compliance with Standards and Regulations

Instrument air systems must comply with various safety, regulatory, and environmental standards, including ASME, ANSI, and local safety codes. These regulations define acceptable standards for air quality, pressure levels, safety measures, and materials. Ensuring that the system design meets these codes while optimizing performance can be challenging, particularly when dealing with complex or highly regulated industries such as petrochemical or pharmaceutical sectors.

11. Space Constraints and Installation

In many industrial environments, space for installing piping systems can be limited, and instrument air piping must be designed to fit within these space constraints. Proper routing of the pipes, careful placement of compressors and receivers, and effective use of vertical and horizontal space are necessary to avoid conflicts with other systems or physical barriers. The installation process also requires precision to ensure proper alignment, adequate support, and sufficient access for maintenance.

12. Redundancy and Reliability

Instrument air systems are crucial for the operation of control systems and instruments in critical processes. Therefore, ensuring system reliability and minimizing the risk of downtime is paramount. Designing the system with redundancy, such as multiple compressors or backup systems, is essential to ensure uninterrupted air supply. Identifying and mitigating potential points of failure and incorporating fail-safe mechanisms is a critical aspect of the design process.

Conclusion

Designing instrument air piping systems involves addressing a variety of technical and practical challenges, from maintaining air quality and pressure consistency to optimizing energy efficiency and ensuring compliance with safety standards. By carefully considering each of these challenges and employing innovative solutions, Divya Design Consultancy helps clients develop reliable, safe, and cost-effective instrument air systems. Our expertise and commitment to excellence ensure that each project is completed to the highest standards, optimizing the performance and reliability of the instrument air supply system.